Project Description

Vertical Conveyor with Chain or Rope Drive

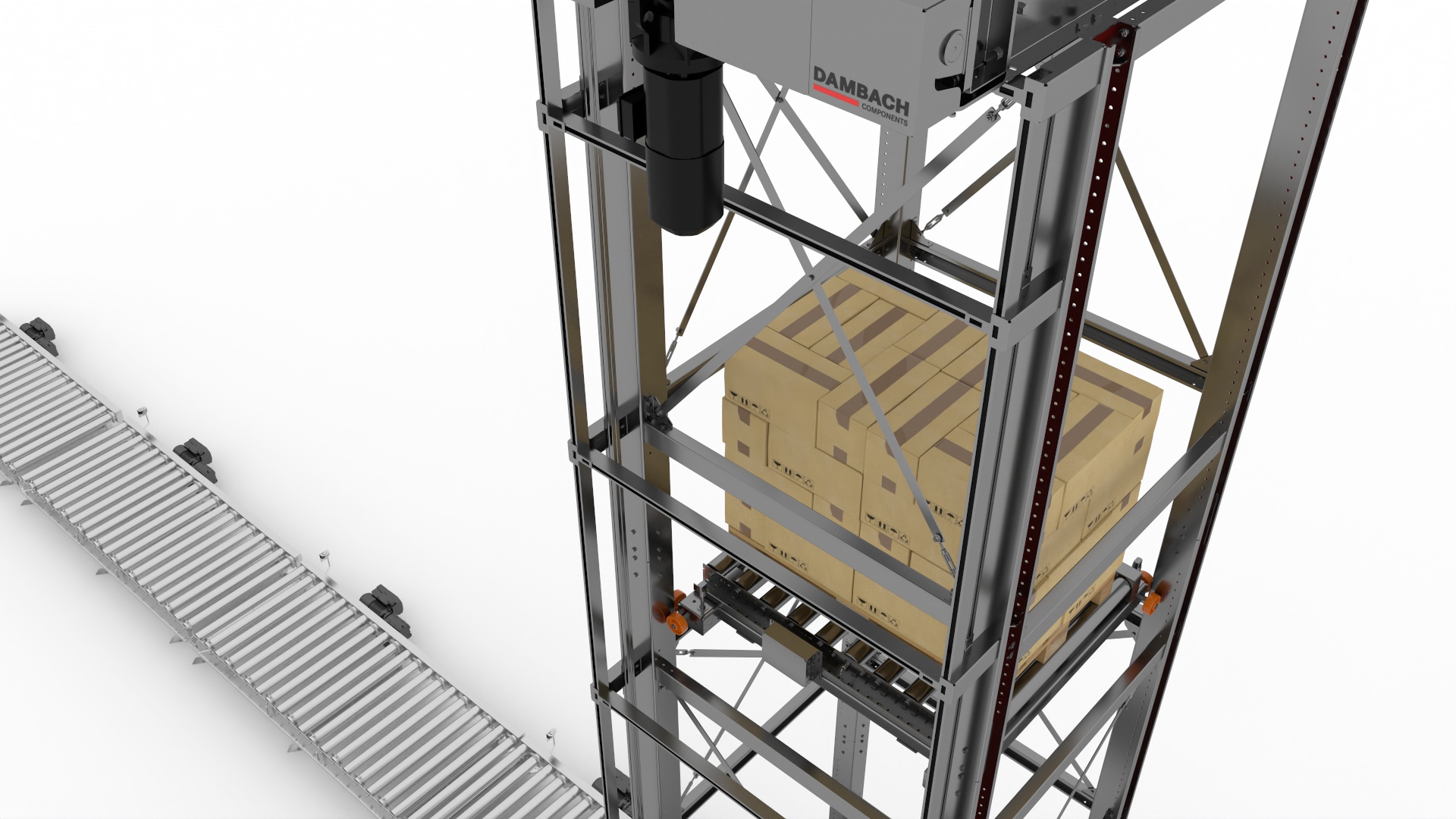

Production buildings and warehouses should always be used as efficiently as possible. Even areas that are well-organized cannot always avoid a change-over from the horizontal to the vertical. The solution: The DAMBACH vertical conveyor, which allows for the quick and easy distribution of products and goods to a number of levels. Further advantages:

■Available assembly spaces are optimally utilized

■Flexible conveyor section planning

■Variable load handling attachment

■Variable transport heights

Technical Data

Payload: Up to 3.000 kg

Temperature: -30 °C to +40 °C

Speed: Up to 240 m/min

Acceleration: Up to 3 m/s²

Flexibly adaptable: the DAMBACH vertical conveyor.

The free-standing frame construction allows optimal usage of storage space – even up to a height of 35 meters. In the truest sense, the DAMBACH vertical conveyor thereby raises efficiency to the next level, and production and warehouse logistics can be further developed professionally. Moreover, the consistent application of “Poka-Yoke-techniques“ and the modular cube design allow for rapid assembly and subsequent installation in cramped conditions. Each lift can additionally be delivered with pre-installation and decentralized control. Suitability for deep-freezing down to -30 °C is obvious with DAMBACH COMPONENTS. The optional design with a casing, safety gear and a counterweight additionally makes the DAMBACH vertical conveyor versatile. It becomes especially useful for high shelf storage, with production processes in the food industry or for the delivery of pallets.

Another advantage is its flexibility. Thanks to versatile load handling attachments and conveyor elements, nearly any material flow can be imagined: for example two pallets lengthwise or transverse or a corner converter with or without a change in direction for the transport unit. In planning the DAMBACH vertical conveyor, existing production structures and other individual requirements are taken into consideration, including for example the quality of the materials that you intend to convey. It can thus be connected to nearly any installation.

Good to know: Features of non-continuous and continuous conveyors.

A non-continuous conveyor with a hoist requires a holding section in the feed, because products arriving must wait for its readiness. The takeover thereby occurs on a lift truck with a roller conveyor or a chain conveyor that transports the product to the next level. For non-continuous conveyors the cycle time is the decisive factor for the throughput.

On the contrary, with continuous conveyors a distinction is made between spiral conveyors and continuous product conveyors. The later are suited above all for the upright transport of products. So-called L-conveyors (mat conveyors) and fork conveyors are available in this case. A special feature of the spiral conveyor is that it prevents accumulation, because it conveys continually. These conveyor technologies are especially suited to high throughputs.

Do you have any questions, suggestions or would you like more information about our products?

Write us via the contact form and we will contact you as soon as possible.